A digital dental workflow with 3Shape, Asiga and Detax resins

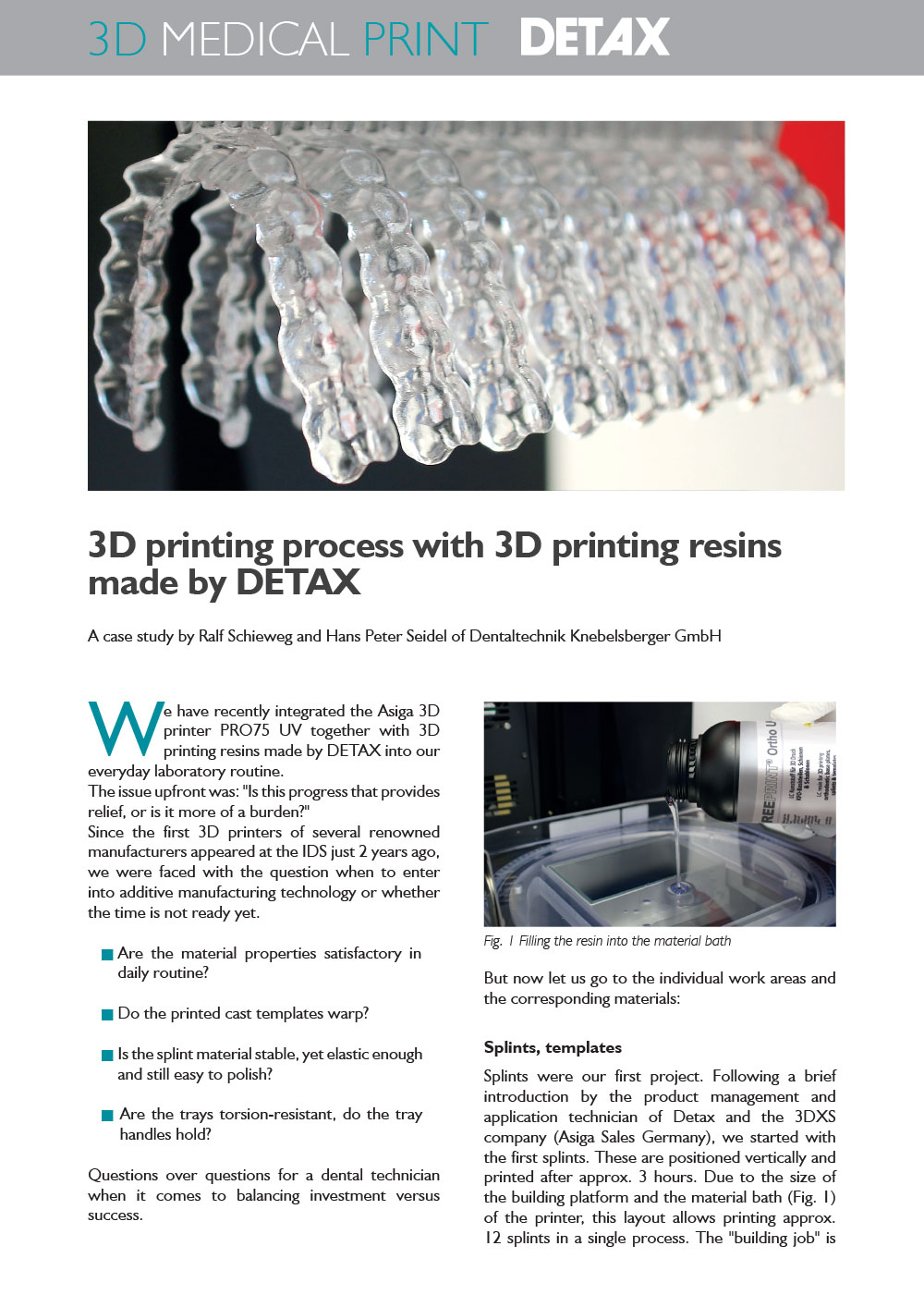

Here is an interesting insight into how German dental laboratory, Dentaltechnik Knebelsberger GmbH process dental materials on the Asiga PRO2 75 UV. From 3D scanning, design, 3D printing, post-curing, delivery to the clinic and ultimately the fit to the patient.

Thank you to Ralf Schieweg and Hans Peter Seidel of Dentaltechnik Knebelsberger GmbH for your time compiling this case study.

Share: