#1 3D printers for hearing aid production

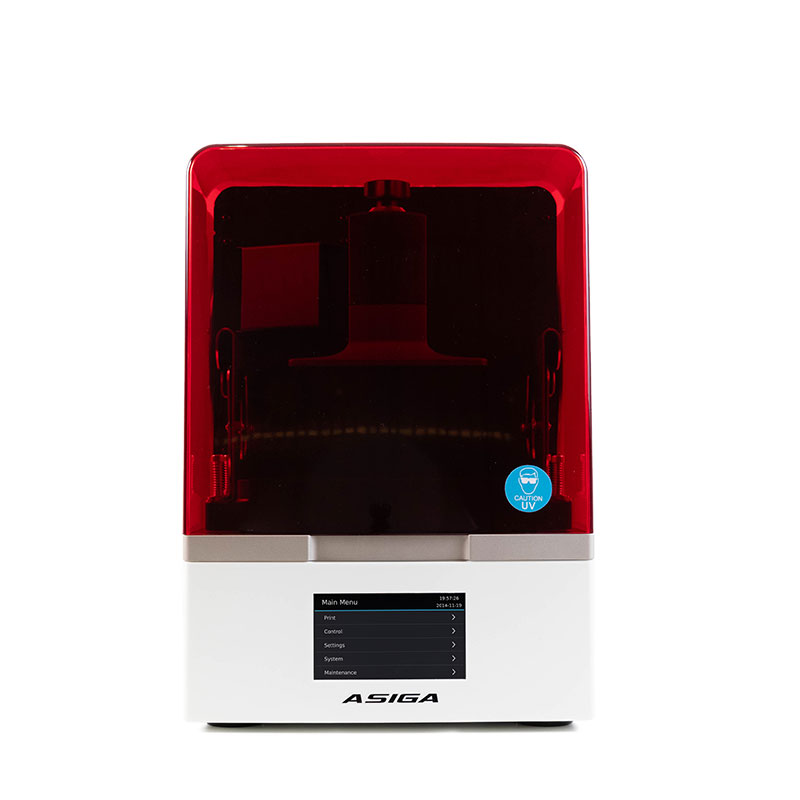

Since 2012 Asiga has supported many of the world’s largest audiology laboratories providing robust production-grade 3D printers.

“Asiga 3D printers really are the crux of our manufacturing process. The accuracy, speed, quality and reliability has revolutionised the way we work.”

Stuart Reid,

GN Resound,

Sydney, Australia

3D print earmoulds, earshells and ear protection

Asiga 3D printers are optimised to manufacture custom-fit hearing devices from BTE to ITE and from ITC to CIC.

Accurately reproduce patient anatomy for product compliance, comfort and fit.

Open Material Freedom

With more than 500 materials available at your finger-tips take control of your production output. Unlimited access to all of the world’s leading audiology materials today, tomorrow and in the future.

Future-proof your business and stay up-to-date with the latest material developments from those who do it best. Optimised, validated, approved materials ready for ‘plug & play’ integration into your workflow.

Nobody does it better!

Hi fidelity In-Ear Monitors

From hearing loss to musical marvels, Asiga 3D printers are widely used to manufacture In Ear Monitors (IEMs) for many leading musicians and for those who are looking for an optimised audio experience at home.

Take advantage of our Open Material Library and select from a range of hearing specific materials. From optically clear rigid materials to heat-activated materials to elastomeric silicones there is a material for every hearing device.

Trusted globally:

The optimum 3D printer for audiology

Choose from our MAX UV or PRO 4K80 UV based on your annual production requirements. See below how each of these 3D printers compare.

MAX UV

Small in size, high in throughput.

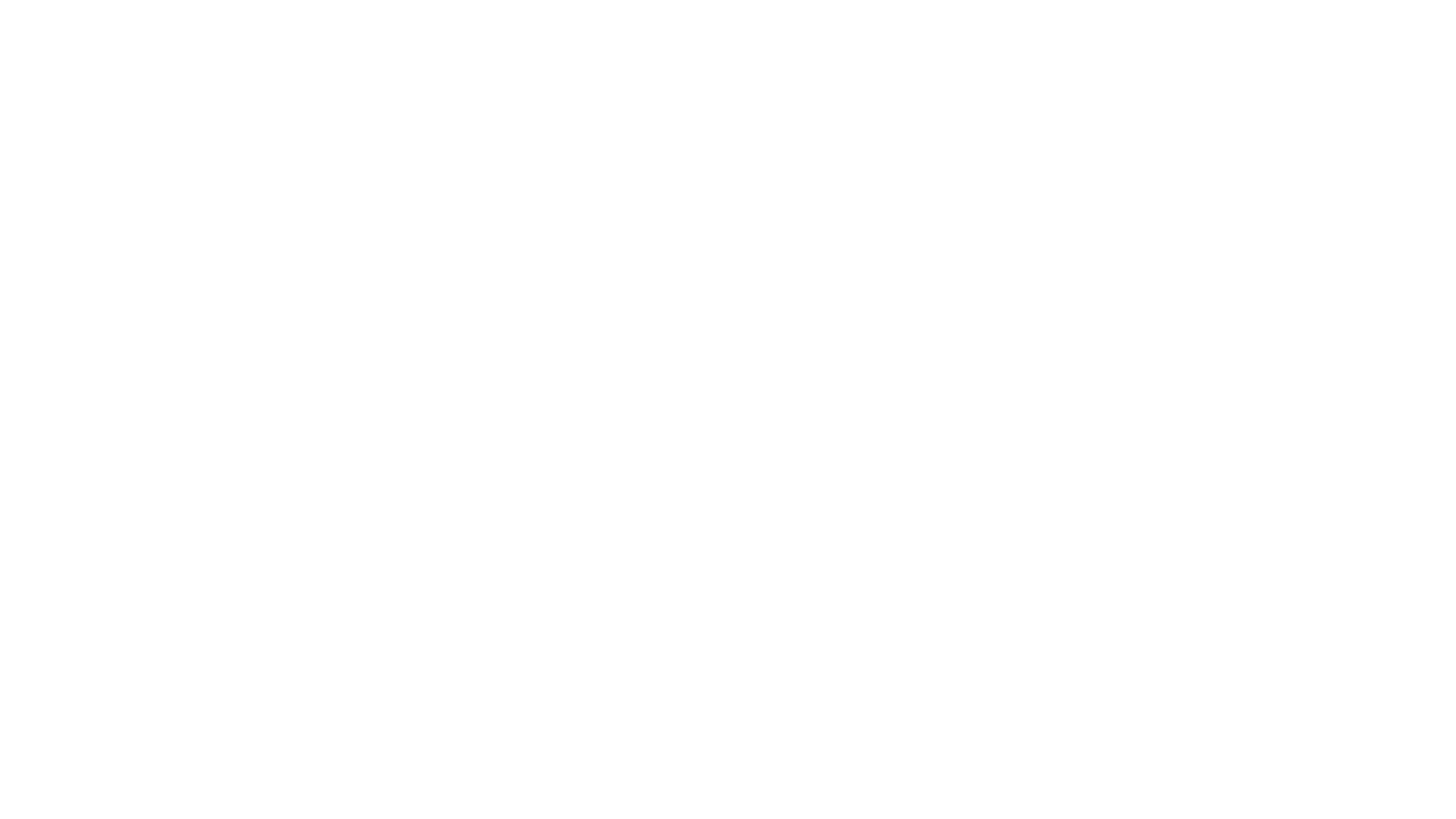

Production output – Shells

Volume

22 shells

Print time

20 minutes @ 100 micron layers

Production capabilities

+60,000 units / year

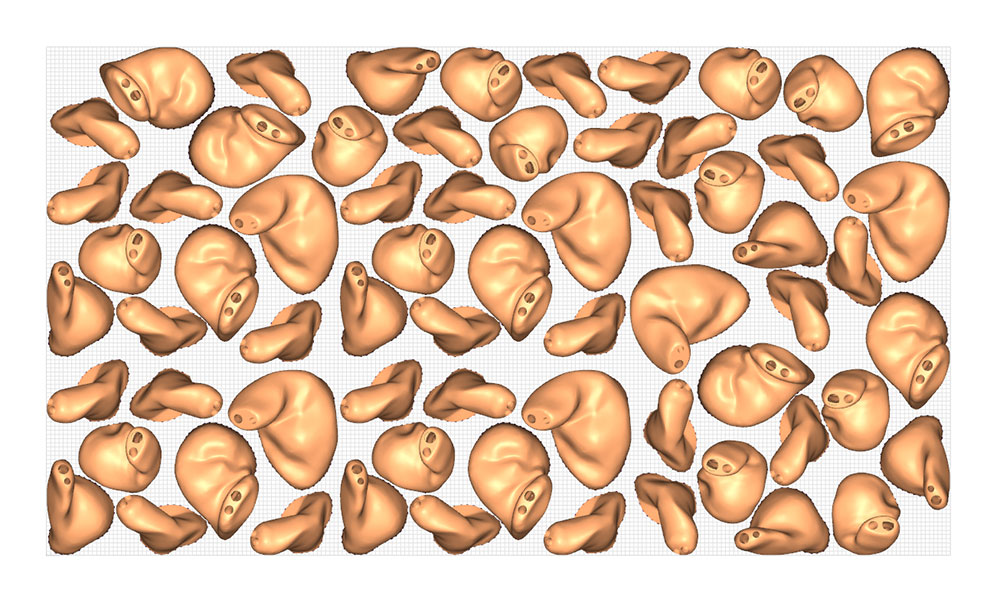

PRO 4K80 UV

High volume audio production.

Production output – Shells

Volume

70 shells

Print time

20 minutes @ 100 micron layers

Production capabilities

+180,000 units / year

Max 2

Built to outperform.

Production output – Shells

Volume

22 shells

Print time

20 minutes @ 100 micron layers

Production capabilities

+60,000 units / year

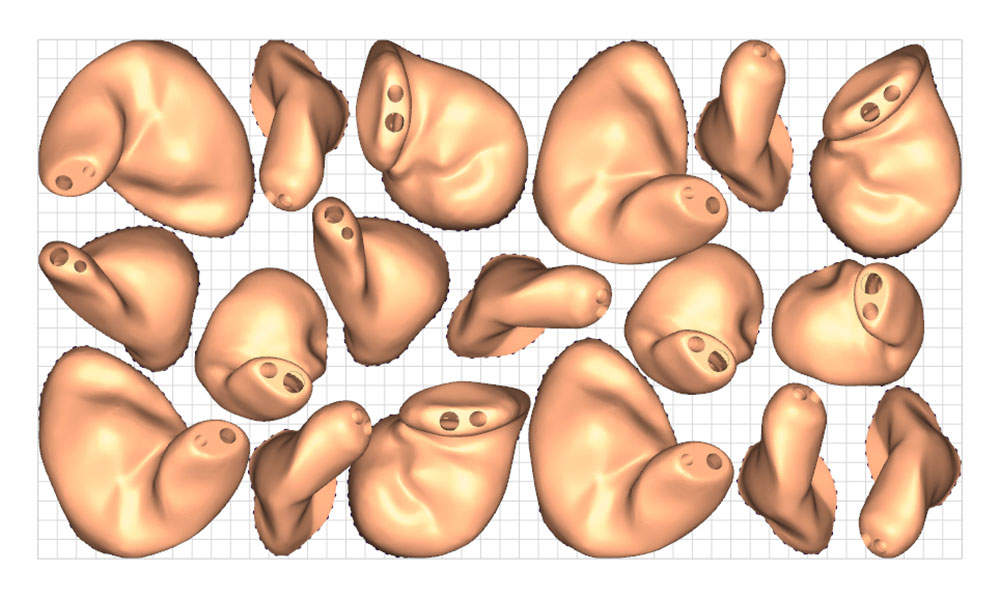

Ultra (50)

Predictable, reliable, smart

Production output – Shells

Volume

44 shells

Print time

20 minutes @ 100 micron layers

Production capabilities

+60,000 units / year

PRO 4K80 UV

High volume dental production.

Production output – Shells

Volume

70 shells

Print time

20 minutes @ 100 micron layers

Production capabilities

+180,000 units / year

A complete digital audio workflow

Impression, Scan, Design, 3D print, Finish and Fit.

Transition to digital today and experience seamless, repeatable workflows and greater client satisfaction.

Hearing Resources

Visit our learning centre to see how our products are used for Hearing.

“Reliability, performance, ease of use, there is no doubt Asiga brings you the future in the present.”

Xavier Martínez Rubio,

Microson

Start your digital journey

Speak to us today about setting up your digital audiology workflow. Compatible with all leading 3D scanner and 3D design software providers companies including 3Shape, Cyfex and Smart Optics.

Design automation in the cloud

Take advantage of AI design automation and benefit from cloud based design solutions from companies such as Hearables3D. AI design automation provides a flexible and accessible solution for digital manufacturing.

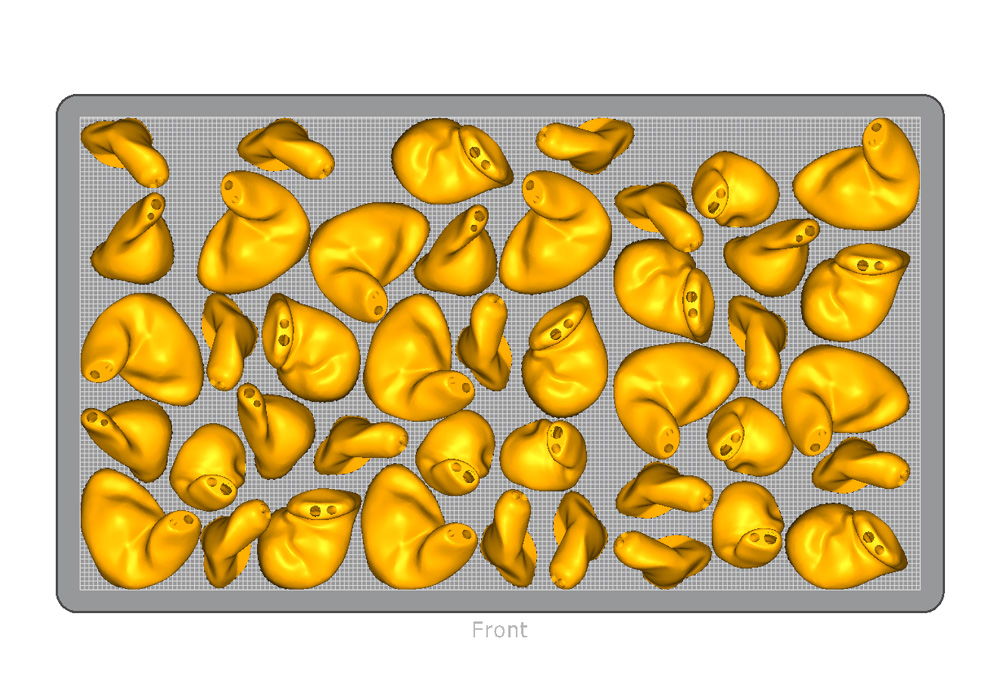

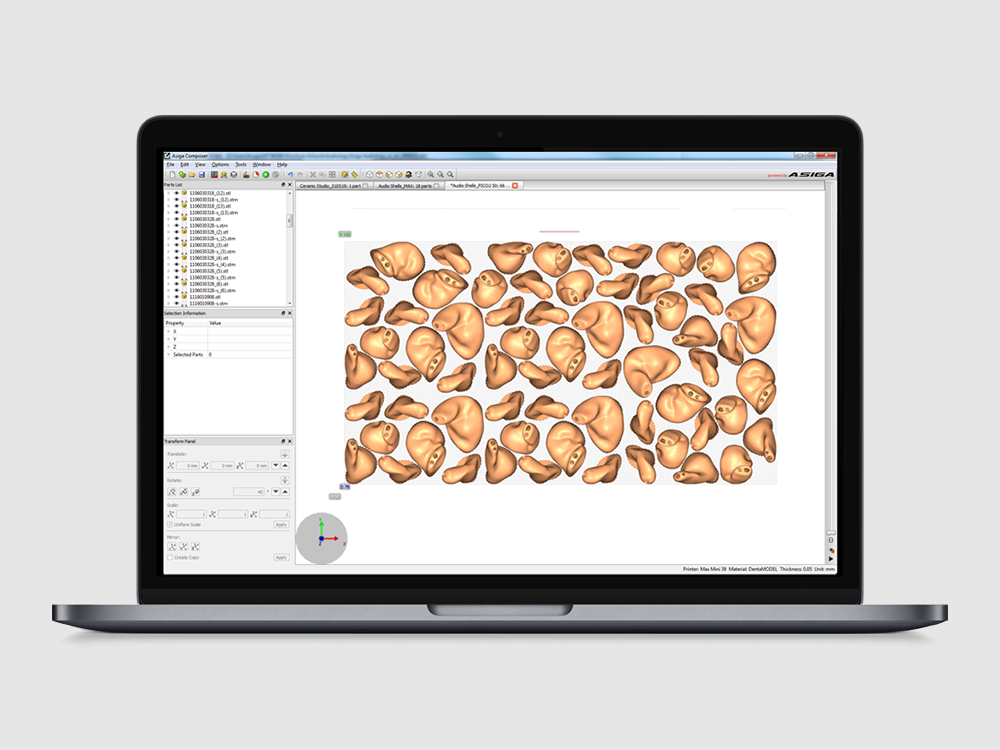

Simple printer set-up

Asiga Composer removes the guess work and provides an automatic job set-up process preparing your parts for 3D printing. For regulatory compliance and data tracking simply export the build log data into an easy to read PDF.

Water-clear 3D printing

Our 385nm UV 3D printers process water-clear materials so hearing devices can be printed clear without any fluorescing or tinting.

Select from a wide range of water-clear audiology materials in our Open Material Library.

Meet high volume demand

Take full advantage of the available Z height on all our 3D printers with the Multi-stacking feature in Composer. The construction of each level in our Multi-stacking feature provides a robust and accurate framework that ensures Z height accuracy is maintained.

Print multiple layers of parts for overnight printing and get the most out of your Asiga 3D printer.

Multi-stacking is a standard feature in our Composer software.

3D printers for Audiology

Contact us today to find out how Asiga 3D printers can enhance your digital capabilities.