Resources

White papers, technical studies

and case studies.

Digital Dental Workflow videos.

An exciting 2 day practical hands-on event hosted at Asiga USA in Ann Arbor, Michigan.

An exciting 2 day practical hands-on event hosted at Asiga USA in Ann Arbor, Michigan.

Dr Diogo Viegas is both a prosthodontist and a dental technician, a rare combination that has given him a comprehensive understanding of dental practice. His experience behind the bench has been invaluable, shaping his professional journey significantly. After dedicating 21…

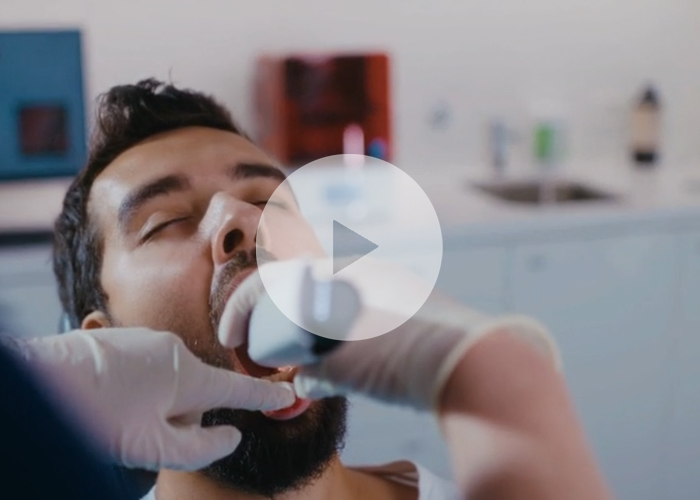

Dr. Nazariy Mykhaylyuk leverages his Asiga 3D printer to deliver precise and rapid dental smile makeovers, creating custom-fit restorations that enhance both aesthetics and functionality. This cutting-edge technology allows him to achieve exceptional results with greater efficiency and personalized care.

Print up to twice as fast.

In this case study, Dr. Nulty delves into how digital technology, including Asiga 3D printers, has positively impacted his treatment protocol for implant restorations from guided surgery to final prothesis delivery.

Asiga at Envision Denture and Implant Center, Canada.

From small beginnings to a fleet of 5 Max. Including the Max 2.

Since 2014, Anne Koelzer of AMK Dental Lab has led the charge to bring digital dentistry to amongst the most rural areas of the United States.

with the Ultra and MAX UV

Marithe Baclagon has earned the title of an Asiga Dental Expert, without doubt. Learn about her journey as a technician and her implementation of digital technology into her profession.

The Max and the Ultra with Dr. Nate Farley & Dr. Kent Howell

My name is Pavel Kijanets, and I was previously in a position as DT/3D Expert in Fibonacci Dental Studio in Tallinn, Estonia. We are a compact dental studio oriented on complex cases and individual approaches. Now, I'm on my way…

Dr Tom Shao, a pioneer of digital dentistry in the clinic.

My path to medicine started in 2016 when my partner, Elena Pachina, an orthopaedic dentist became my inspiration and guide to this profession. My name is Anton Melnikov and I am a dental technician.

Don't miss this deep-dive case study covering Dr. Giglio's digital record-taking technique for implant restorations.

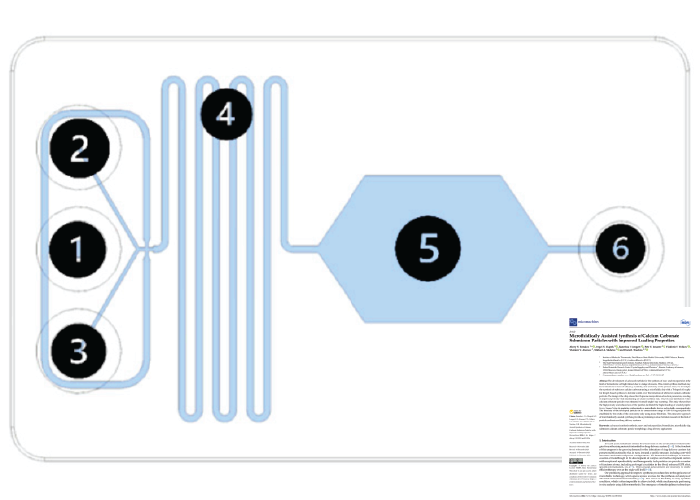

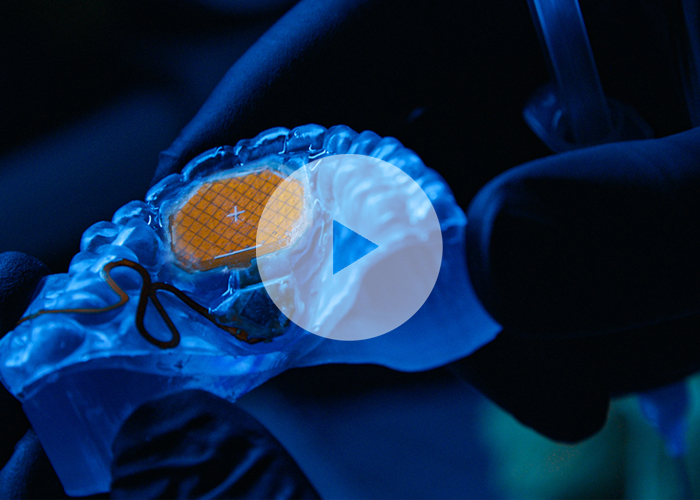

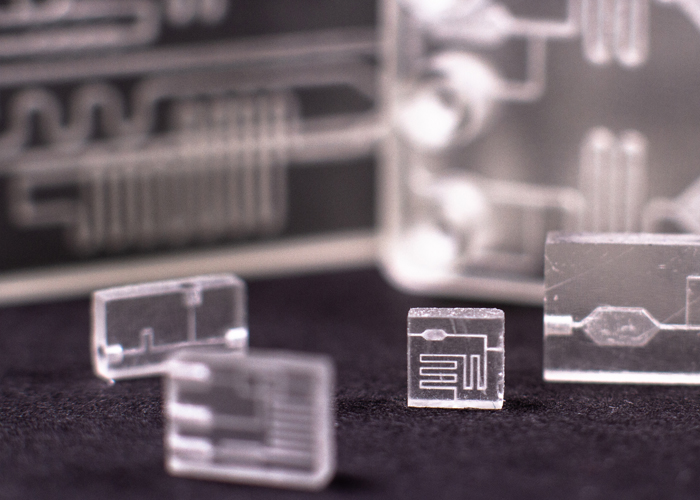

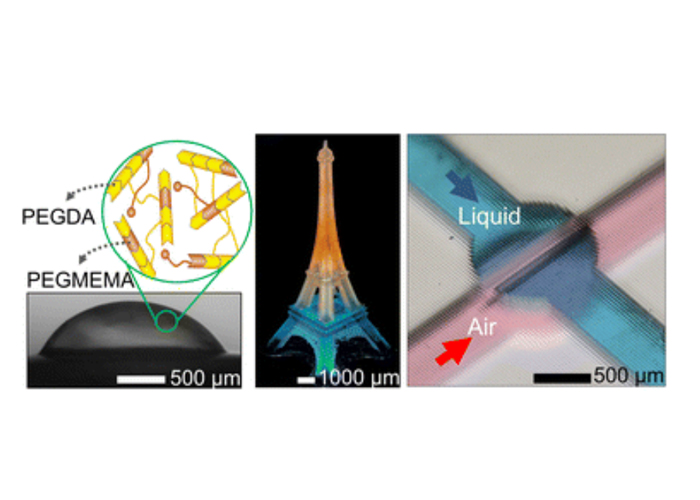

The development of advanced methods for the synthesis of nano- and microparticles in the field of biomedicine is of high interest due to a range of reasons. The current synthesis methods may

have limitations in terms of efficiency, scalability, and uniformity of the particles. Here, we investigate

the synthesis of submicron calcium carbonate using a microfluidic chip with a T-shaped oil supply

for droplet-based synthesis to facilitate control over the formation of submicron calcium carbonate

particles.

For decades, Plasson had been a pioneer and market leader in the field of plumbing and irrigation systems across multiple industry sectors and disciplines. The dawn of new markets and materials Industry 4.0 brought with it a new set of…

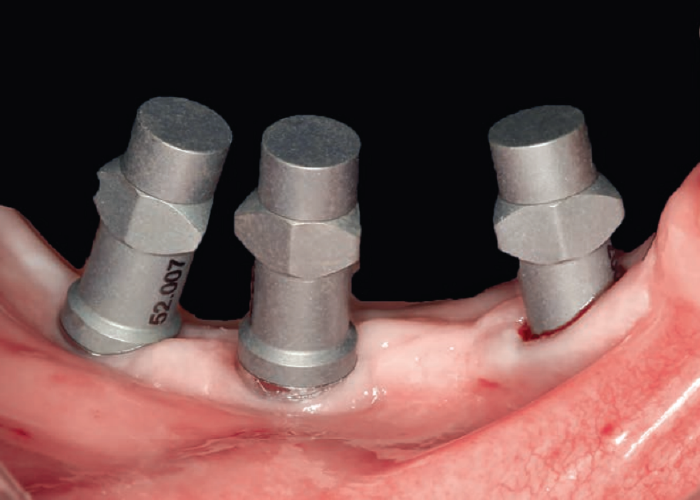

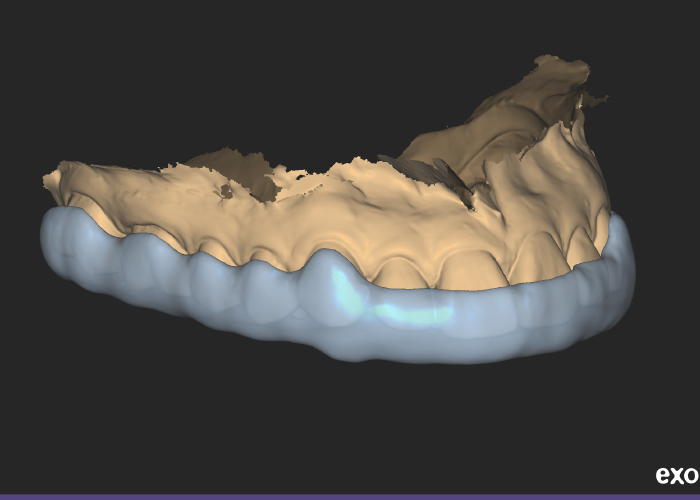

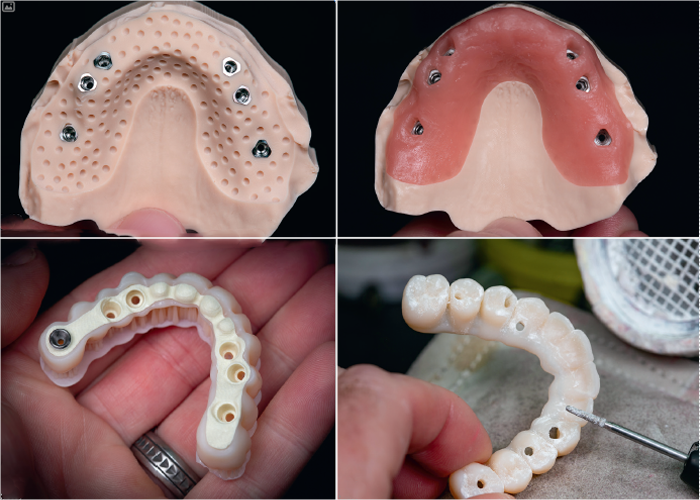

In this case report, we will share how CAD software and CAM hardware can create a predictable and innovative provisional implant restoration which not only satisfies the patient, but also the clinician and dental designer/technician.

Learn how Dr. Ahmad Al-Hassiny has transformed his night guard fabrication utilizing the Asiga MAX 3D printer in this start-to-finish case study.

See the initial thoughts of Dr. Ahmad Al-Hassiny of the all-new Asiga Ultra 3D printer. Featuring Asiga's SPS layer-monitoring technology, open materials system, and brand new Transparent Mode and IR heating technology, the Asiga Ultra is our most-advanced 3D printer to date.

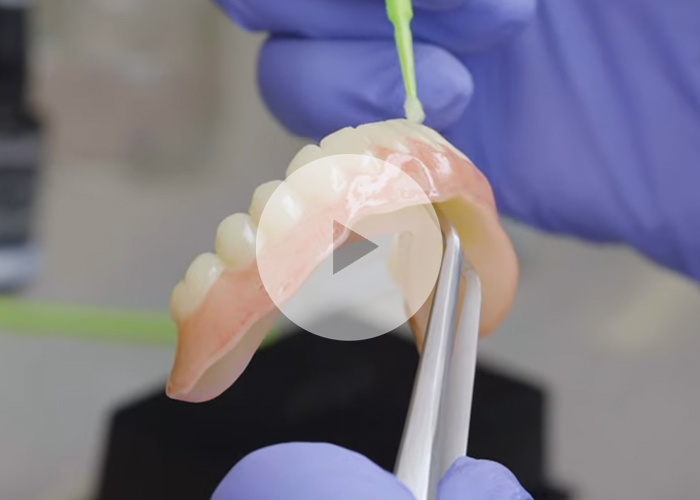

Fabrication of a long-term prototype to develop and sculpt anterior gingival tissue This article shows the step-by-step laboratory production process of a long-term prototype for the development and sculpting of anterior gingival tissue. Read the Full Article About the author…

After a 6 year career in the NFL as a Tight End and Fullback for the Pittsburgh Steelers, Matt Cushing entered the dental lab industry as a sales rep. After building relationships in the dental community for a few years, he had the opportunity to start First Choice Dental Lab in 2008. First Choice has grown into a full service dental lab offering crown and bridge, removables, implant, and full arch work.

Discover how Dental Artistry Implants Crowns and Veneers utilizes their Asiga MAX UV for full mouth rehabs, dentures, splints, and more!

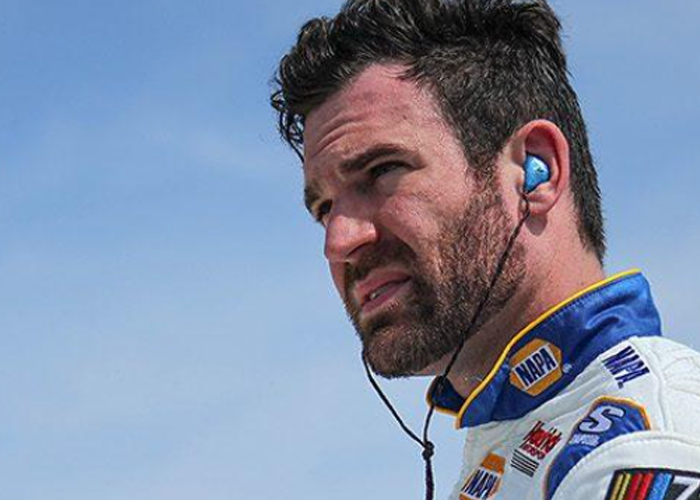

In the high-speed, adrenaline-fueled world of NASCAR, communication between drivers and their teams is paramount for success.

Empowering, ground-breaking and ingenious.

When you are working in the maxillofacial, surgical and dental world, there is no room for error. Lee Culp, Sculpture Studios

Founded in 1985 by Dr. John Roe, ROE Dental Laboratory began as a small, family-owned dental laboratory.

Join us behind the scenes at iDENTity Dental Studio with Dr. Brandon Stapleton

Case study with Bachmaier and Henkel Loctitie

Through the doors at one of the most progressive dental laboratories in the US

And, meet Tilly Talbot, the world’s first AI-Powered Designer

LDBE, AI design & Asiga

by Adam Wojciechowski, Demant

Fully automated with 3Shape Nightguard Automate Stage 1 Intra-oral scan - 3Shape Trios Stage 2 AI Design - 3Shape Automate Stage 3 UltraGLOSS™ 3D print - Asiga MAX UV or PRO 4K80 UV using Keysplint Keystone Soft Stage 4 Wash…

A summary of the top 5 microfluidic devices by Sergei Chapek

Asiga at G Dental in New York

A personal account of the benefits of using third-party materials in dental laboratories by Przemek Seweryniak

By Alireza Ahmadianyazdi, Isaac J. Miller and Albert Folch

Making Life Sound Better, GN Hearing

3D Printing All-On-X Applications

Asiga How-to education series

Asiga How-to education series

Asiga How-to education series

Asiga How-to education series

Asiga How-to education series

Asiga How-to education series

Asiga How-to education series

Asiga How-to education series

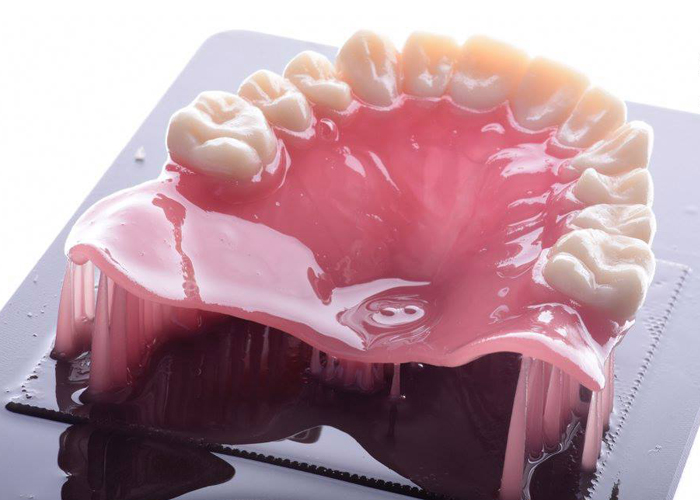

A full digital denture workflow