My Journey with Asiga Printers

By Przemek Swereyniak, Cosmodent AB, Sweden

As a dental technician who has tried various 3D printers in my day-to-day dental laboratory operations, I can confidently say that the Asiga Max UV and Pro 4K printers surpass other brands when it comes to versatility, precision, and user-friendliness. A major benefit of these printers is their ability to work seamlessly with third-party materials, giving me the freedom to select the most suitable resins for my unique needs. In this article, I’ll share my journey with Asiga printers, showcasing the advantages of using third-party materials and explain why I firmly believe that these printers are indispensable for contemporary dental laboratories.

Third-Party Material Compatibility: A Game Changer

In contrast to certain 3D printer manufacturers that restrict users to their proprietary materials, Asiga printers are engineered to accommodate a broad spectrum of third-party resins. This adaptability allows me to choose the most appropriate materials based on my particular needs, including factors like strength, biocompatibility, and aesthetics. Moreover, this compatibility has enabled me to explore and experiment with new materials and technologies as they surface, guaranteeing that my dental laboratory remains on the cutting edge of dental advancements.

One of the most notable advantages I’ve enjoyed while using third-party materials with Asiga printers is the cost-effectiveness. The liberty to choose from a diverse range of materials has enabled me to find budget-friendly options that achieve the desired outcomes without sacrificing quality.

For our dental lab incorporating third party materials has been a crucial factor in staying competitive amidst an ever changing market landscape. With this capability comes the ability to develop customized workflows designed explicitly for individual clients’ needs resulting in exceptional clinical outcomes and satisfied patients overall. By thoughtfully selecting specific materials based on patient preferences we can deliver highly personalized results with impressive accuracy.

By working with third-party resins, I’ve managed to benefit from the most recent breakthroughs in material science, resulting in enhanced mechanical properties, durability, and aesthetics in the final restorations. Moreover, having the flexibility to switch between various resins depending on specific requirements has made my production process smoother, leading to greater efficiency and minimized downtime.

“Compatibility with third-party materials, exceptional performance and ease of use, makes Asiga an ideal choice for dental laboratories “

Prezemek Seweryniak, Cosmodent AB

Asiga UV Max and Asiga Pro 4K: My Preferred Choice for Dental 3D Printing

In my experience, Asiga printers, including the Max UV and Pro 4K models, boast several features that make them ideal choices for dental laboratories. One of the features I love most with the printers is the automatic light calibration, which ensures accurate and consistent results across all prints. This eliminates the need for manual calibration and reduces the risk of errors, saving me time and resources.

Both the Asiga Max UV and Pro 4K printers offer high-resolution printing capabilities, producing highly detailed and accurate dental prosthetics. This level of detail is crucial for ensuring proper fit and function in the final restoration, leading to increased patient satisfaction and reduced chairside adjustments.

The Asiga printers are designed for speed and efficiency, reducing the production time for dental prosthetics. This efficiency has allowed me to complete more cases in less time, improving my overall productivity and competitiveness in the market.

Equipped with an intuitive user interface, Asiga printers are easy to operate, allowing me to manage my workflows seamlessly. This user-friendly design has reduced the learning curve for me and has contributed to the overall efficiency of my dental laboratory.

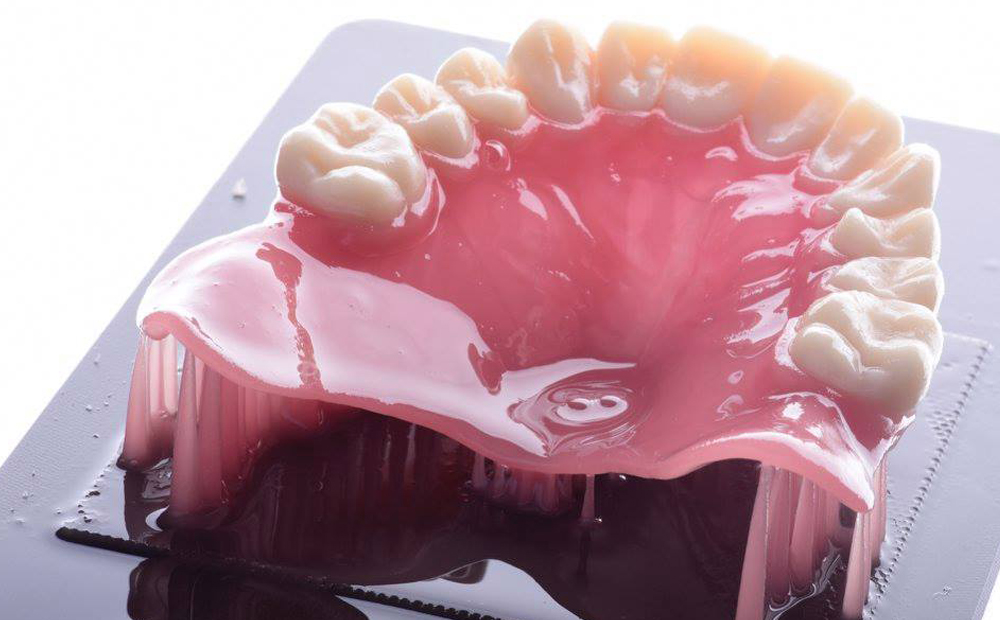

Diverse Applications: Surgical Guides, Dentures, and Diagnostic Waxup Models

The flexibility offered by the Asiga printers extends to their diverse range of applications. My dental laboratory has been able to produce a variety of dental products, including surgical guides, dentures, and diagnostic wax-up models, by utilizing the appropriate third-party resins. This versatility allows me to cater to a wide range of needs and offer comprehensive solutions for our customers.

For example, surgical guides need both high precision and biocompatibility, which can be attained by using suitable third-party resins along with Asiga printers’ exceptional high-resolution printing capabilities. In the same vein, dentures call for a fine balance of strength, durability, and aesthetics, which can be accomplished through the meticulous selection of materials. On the other hand, diagnostic wax-up models benefit from resins that are easily shaped and adjusted as required with the handpiece and polish well to obtain perfect stents for provisionals or injection molds.

The Road Ahead: Embracing Flexibility and Innovation

As the dental industry continues to evolve, the ability to adapt and stay ahead of the curve is vital for success. In my experience, Asiga printers, with their compatibility with third-party materials, have been instrumental in helping my dental laboratory thrive. Their versatility, precision, and user-friendly design make them an invaluable tool in modern dental labs. By staying open to new materials and technologies, we can always test the latest and greatest and see if we can implement new resins or products quickly. This adaptability has not only improved the quality of my work but also ensured my dental laboratory remains competitive and relevant in an ever-changing industry.

In summary, my journey with Asiga printers has shown that their compatibility with third-party materials, exceptional performance and ease of use, makes them an ideal choice for dental laboratories looking to excel in today’s dynamic dental landscape.

For more information on Przemek and Cosmodent AB visit their website here >

Share: