MOIIN Resins presents its high-precision resins for microfluidics at the EMBL Microfluidics Conference

Producing narrow channels and cavities with transparent, photopolymerizing 3D printing resins can be extremely difficult – but it’s entirely possible with the high-quality MOIIN resins developed in Hamburg. Dr Jens Träger, head of the Digital Application Centre at DMG Digital Enterprises SE and innovation coach, recently exemplified this at the “Microfluidics 2022” conference in Heidelberg.

The EMBL Microfluidics Conference promotes the sharing of scientific expertise in a variety of fields, ranging from fundamental physics and chemistry to device design and emerging biological applications. The event brings together academic researchers and those from other research settings, industry colleagues and microfluidics practitioners.

Overcuring problem solved

Until now, minor and more serious deviations in 3D printing results have been a matter of course when using photopolymers. Overcuring is one of the reasons behind such print object inaccuracies. It is particularly prevalent in transparent materials and can cause considerable difficulties, especially when creating precise internal structures and cavitations.

How did MOIIN address this challenge in the development of its 3D printing resins?

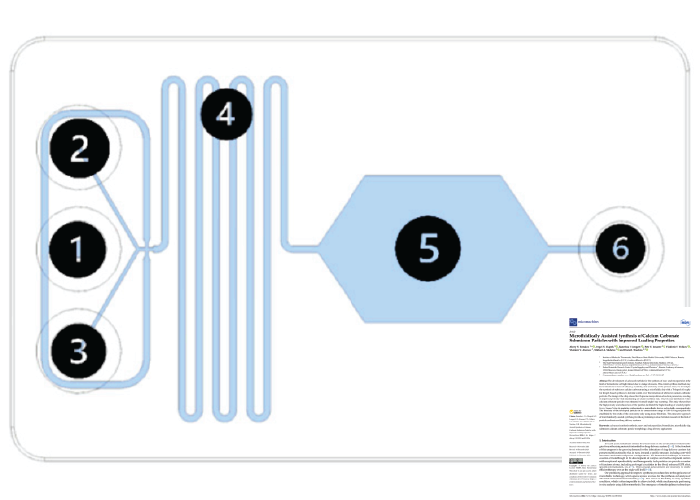

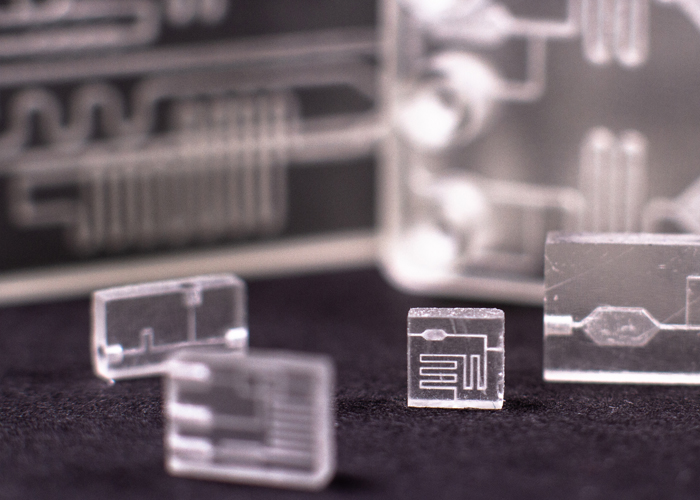

“The key lies in the targeted optimisation of the material’s photochemical behaviour under a 3D printer light source. The special CDB (Cure Depth Barrier) technology, which transparent MOIIN resins feature, reduces unwanted overcuring to a minimum. This technology, for example, enables the precise production of capillaries with an inner diameter of approx. 1 mm and a wall thickness of just 100-200 micrometres. The best possible matching of printer and material is also worth mentioning here. The 3D printing was carried out using MOIIN Tech Clear in combination with an Asiga Max UV printer”

explained Dr Träger, presenting an impressive user case in which an object, developed by the Deutsches Elektronen-Synchrotron DESY for the generation of terahertz radiation was 3D printed and successfully tested.

Microfluidics innovation driver

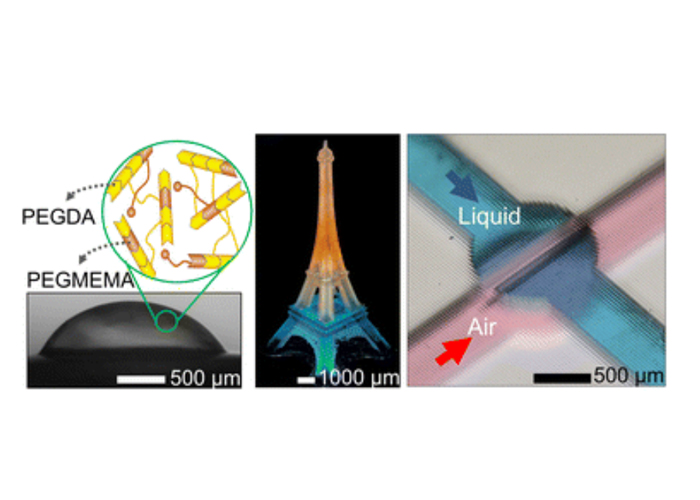

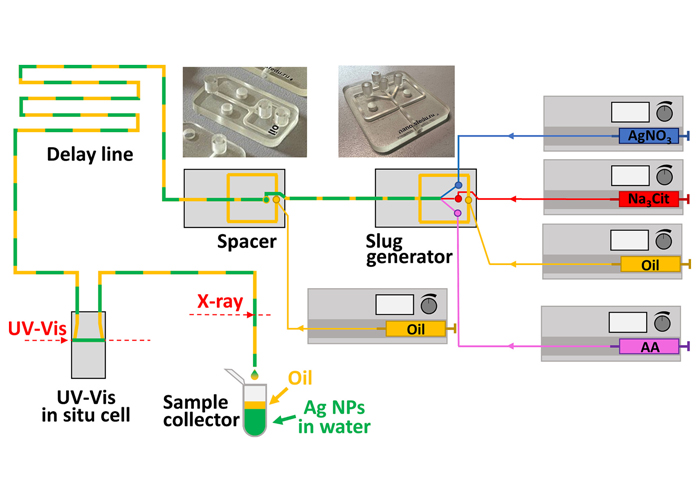

Microfluidic tools have facilitated enormous progress in biological and biomedical research. Highly-complex miniature components are created through collaborations spanning the fields of physics, engineering, chemistry and biology. Revolutionizing innovations in areas such as nucleotide sequencing, functional genomics, single cell/molecule studies, and biomedical diagnostics are made possible thanks to microfluidics.

Not only does miniaturization on a picolitre to nanolitre scale allow for optimal parallelization, it also offers excellent spatial and temporal control. The smallest of objects, such as cells, or even parts of them, can be exposed to unique conditions, which opens up completely new investigative approaches in modern biology and chemistry.

For more information, please visit www.moiin-resins.com

Share: